Lödige as a partner for the

food industry

Lödige systems offer the required mixing and process precision for an ideal process design in a wide production range. Our customers include notable food industry brands. Our systems and solution concepts are used worldwide, based on decades of practical experience in the construction of mixers and treatment systems for food producers. It goes without saying that we provide a “Hygienic Design” of our machine engineering solutions and also implement extensive cleaning systems.

Our machines are built according to current international regulations for food-safe hygienic design and are adapted perfectly to your process through customer- and product-specific adaptation. Our range of services is supplemented by extensive after-sales support.

Process engineering solutions

Based on numerous process engineering options, Lödige systems can be designed and used for numerous products and production steps. For instance, in addition to the conventional mixing step, it is possible to combine the additional process steps usually required by the food industry in one Lödige system. This can make, for example, work-intensive pre-mixing unnecessary. All systems listed below are available both in production sizes and in sizes suitable for Laboratory work.

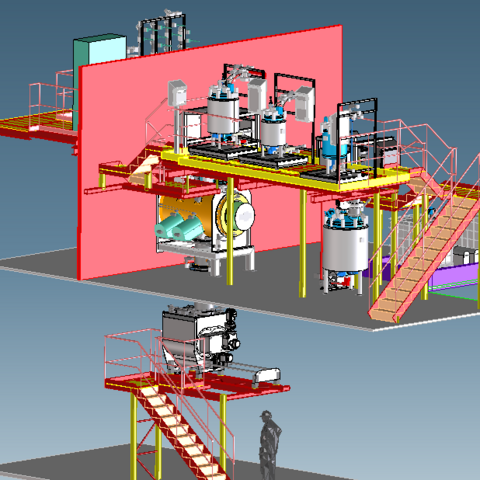

Turnkey solutions from Lödige for the food industry – make use of expertise for tailor-made complete solutions

We manage your entire project efficiently and with minimal interfaces, right up to the complete assumption of technical and commercial project responsibility. So put your trust in our expertise and plan your next turnkey project with Lödige!

Machines for the food industry

Lödige provides various mixing, granulation, drying and fluidised bed systems for the different process engineering based production steps required in the food industry. Check the following list for an overview of the individual machines suitable for the food industry.

Mixing granulator (Laboratory machine)

Laboratory mixing granulator with exchangeable vessel Mixing, granulation and temperature control in one machine Exchangeable vessels with a volume of 1, 5, 10 or 15 l GMP-compliant design User-friendly, integrated control system Operation-ready system

Ploughshare® Mixer (Laboratory machine)

Guaranteed Lödige quality Attractive value for money Functional design Ideal for your product and process development Extensive range of accessories

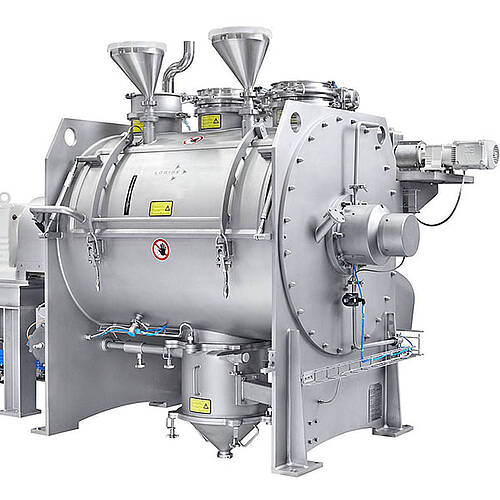

Ploughshare® Mixers for batch operation "Hygienic Design"

We develop customised solutions, adapted perfectly to your application and product, for any of your tasks. Extremely high mixing quality Short mixing times Reproducibility of batches Gentle product treatment High availability Low-maintenance mixer concept Easy accessibility of all internal mixer components Multi-stage processes in one machine

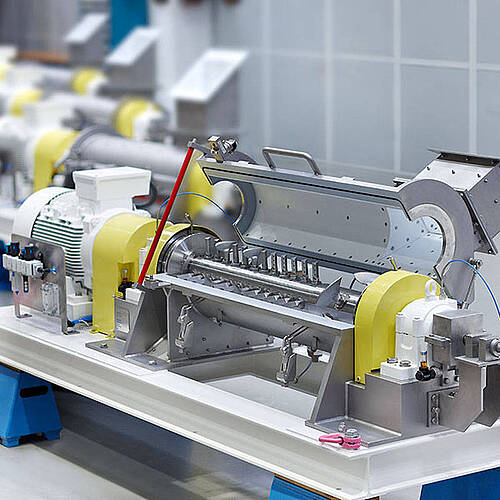

Ringlayer mixer CoriMix® for continuous operation

Compact machine unit with high throughput Extremely high mixing homogeneity Versatile application options Easy operation and cleaning High operating reliability and service life

The mixing granulator

Mixing granulator for pharmaceutical products, cosmetics and food GMP-compliant design Modular WIP system for the machine and all additional components Automatic liquid addition in different versions New pharmaceutical controls Temperature control jacket for heating/cooling Integrated sieve on machine outlet Vacuum feeder Customised ATEX concepts

The wet mixer

High mixing quality even for critical products Application of high shearing forces Easy operation and cleaning Reliable and time-tested mixer concept

Applications for the food industry

Lödige looks back at a long history of success in the food industry segment. In the 80 years since the company was founded, Lödige has introduced a large variety of machines for different applications to the market. Ploughshare® Mixers using the mechanical fluidised bed process developed in-house make up the majority of these. Lödige machines are reliable components of production lines, both for small family-owned companies and of global corporations with high-volume production. It is frequently possible to combine process steps based on different principles in our systems. Check the following list for a small excerpt of process engineering applications for the food industry which use our products.

- Ready-to-cook dried soups

- Oven-ready flours/bake mixes to which fat and lecithin are added

- Spices/food salts

- Flavours / flavouring substances

- Instant drinks, dry and with added flavour

- Coffee and tea extracts/tea mixes

- Dietary supplements/vitamins

- Tobacco

- Confectionery/chocolate

- Granola/cereals

- Milk/whey powder/baby food

- Enzymes/starter cultures

- Creams/dressings/mustard

- Cheese/soft cheese melts

CONTACT PERSON

Downloads

System Solutions for the Food Industry